Aquaristics, especially marine, requires a deep understanding of filtration processes and maintaining the ideal chemical balance of water. Unlike freshwater systems, where the main load falls on biological filtration and regular water changes, marine reef aquariums need an aggressive mechanism to remove organic compounds before they break down into nitrates and phosphates. This is precisely the critical function performed by a protein skimmer (also known as a foam fractionator).

Protein Skimmer for Marine Aquariums: Why It’s Needed and Why It’s the ‘Heart’ of the System?

A marine aquarium is a closed ecosystem with a high population density and active metabolism. Fish, invertebrates, and corals constantly excrete waste products, which collectively form what are known as dissolved organic compounds (DOCs). If not removed, these compounds quickly lead to deterioration of water quality, the growth of undesirable algae, and ultimately, stress and death for sensitive corals (e.g., Acropora sp.) or fish.

The protein skimmer has earned the title of the “heart” of a marine system because it is the only device that exports organic matter from the water, rather than just converting it (as a biological filter does).

- Prevention of Nitrate Accumulation: By removing organic matter in its early stages, the skimmer reduces the load on the biological filter.

- Improved Gas Exchange: Active mixing of water with air promotes water saturation with oxygen (O₂) and removal of carbon dioxide (CO₂).

- Increased Water Clarity: The removal of microscopic suspended particles makes the water crystal clear.

- pH Stabilization: The removal of CO₂ helps stabilize the pH level, which is critical for coral growth.

What is a Protein Skimmer and What Substances Does It Remove from Marine Water?

A protein skimmer is a device that operates on the principle of foam fractionation. This method is based on the phenomenon of adsorption: organic molecules are hydrophobic (water-repellent) and tend to attach to the interface between phases – in this case, the surface of air bubbles.

The main list of substances effectively removed by a protein skimmer:

- Proteins and Amino Acids: Direct breakdown products of food and metabolic processes.

- Phenols and Lipids: Fatty and oily substances.

- Urea and Ammonia: Intermediate nitrogenous compounds.

- Yellowing Agents: Organic pigments that, over time, give the water an unpleasant yellowish tint.

Important to understand: The more concentrated the marine water (the higher the salinity), the more effectively the skimmer works, as the high salt concentration increases surface tension and promotes stronger adhesion of organic molecules to the bubbles.

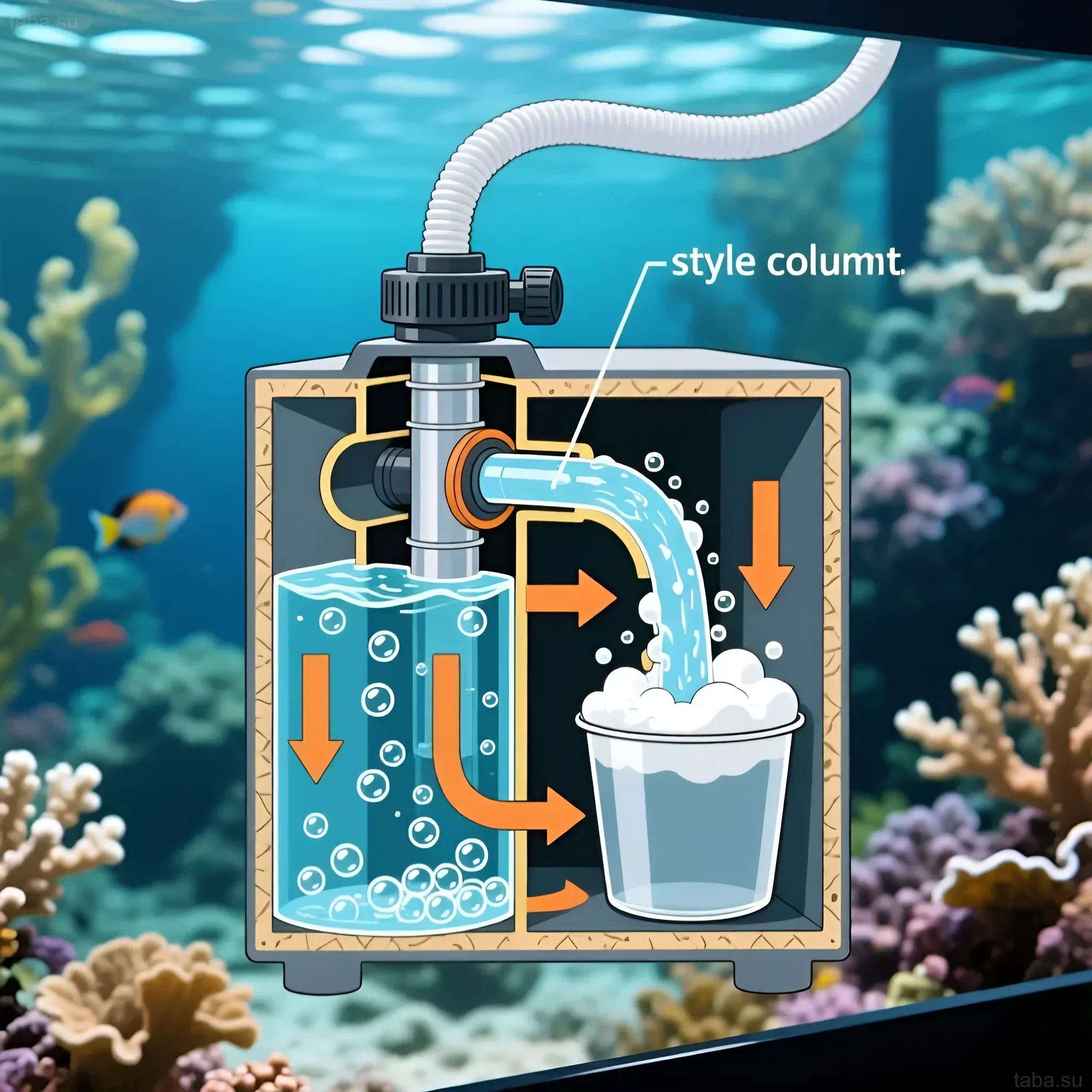

How a Protein Skimmer Works: From Air Pump to Stable Foam

The operation of a protein skimmer may seem complex, but it is based on a simple physical process. There are several design variations, but the general scheme of functioning remains unchanged:

1. Mixing and Bubble Generation

Water from the aquarium (or sump) enters the reaction chamber. Inside the chamber, a powerful pump, equipped with a special impeller (e.g., a needle wheel), draws in air and water simultaneously. The impeller breaks the air into a huge number of microscopic bubbles. The smaller and more numerous the bubbles, the larger the total surface area available for adsorption.

2. Organic Adsorption

Inside the reaction chamber, organic molecules, seeking to avoid contact with water, are attracted to the surface of the air bubbles. This process takes time, so the longer the bubbles are in contact with the water (the taller the reaction chamber), the more effective the purification.

3. Concentration and Ascent

As the bubbles rise up the chamber, they collide with each other, forming larger clusters. These clusters, saturated with organic matter, form a dense foam. The skimmer’s design features a constriction at the top – the neck. This constriction forcibly concentrates the foam, “squeezing” excess water out of it.

4. Waste Collection

The dense, dark foam rises through the neck and overflows into a removable collection cup. In the cup, the foam breaks down, leaving behind a concentrated, foul-smelling liquid – waste that must be regularly removed from the system.

Key factor for effectiveness: Contact time (contact time between water and bubbles) and bubble size. Modern skimmers use high-efficiency DC pumps and needle wheels to achieve the smallest and most stable bubbles possible.

Types of Protein Skimmers for Marine Aquariums: Choosing the Optimal Option

The choice of a specific skimmer model depends on the aquarium size, budget, and system configuration (presence of a sump).

Classification by Installation Location

- In-Sump Skimmers:

This is the most popular and effective type. They are installed directly in the sump compartment (technical aquarium below the main display). They are quiet, aesthetically pleasing, and maintain a stable water level, which is critical for their operation. - Hang-On-Back (HOB) Skimmers:

Ideal for aquariums without a sump (nano reefs or small systems). Part of the pump and reaction chamber is inside the aquarium, and the collection cup hangs outside. They require more careful monitoring of the water level in the main aquarium. - External/Recirculating Skimmers:

Used in very large or complex systems. They are placed outside the sump or aquarium and require a separate feed pump. They provide maximum performance.

Classification by Air Supply Method

- Needle Wheel Skimmers:

The industry standard. The pump is equipped with an impeller with fine “needles” that literally “whip” water and air, creating the smallest and densest foam possible. High energy efficiency and performance. - Venturi Skimmers:

Air is drawn in through a special opening in the pump (Venturi effect). Less common today, as they often create larger bubbles compared to needle wheels. - Air Stone Skimmers:

Older or budget models. They use a compressor and a wooden air stone (usually linden wood) that creates bubbles. They require frequent replacement of the air stone and have low performance for large volumes.

Protein Skimmer Installation and Setup: A Step-by-Step Guide for Beginners

Proper skimmer setup is the key to its long-term effectiveness. An incorrectly installed skimmer will either be “dry” (collect very little) or constantly overflow.

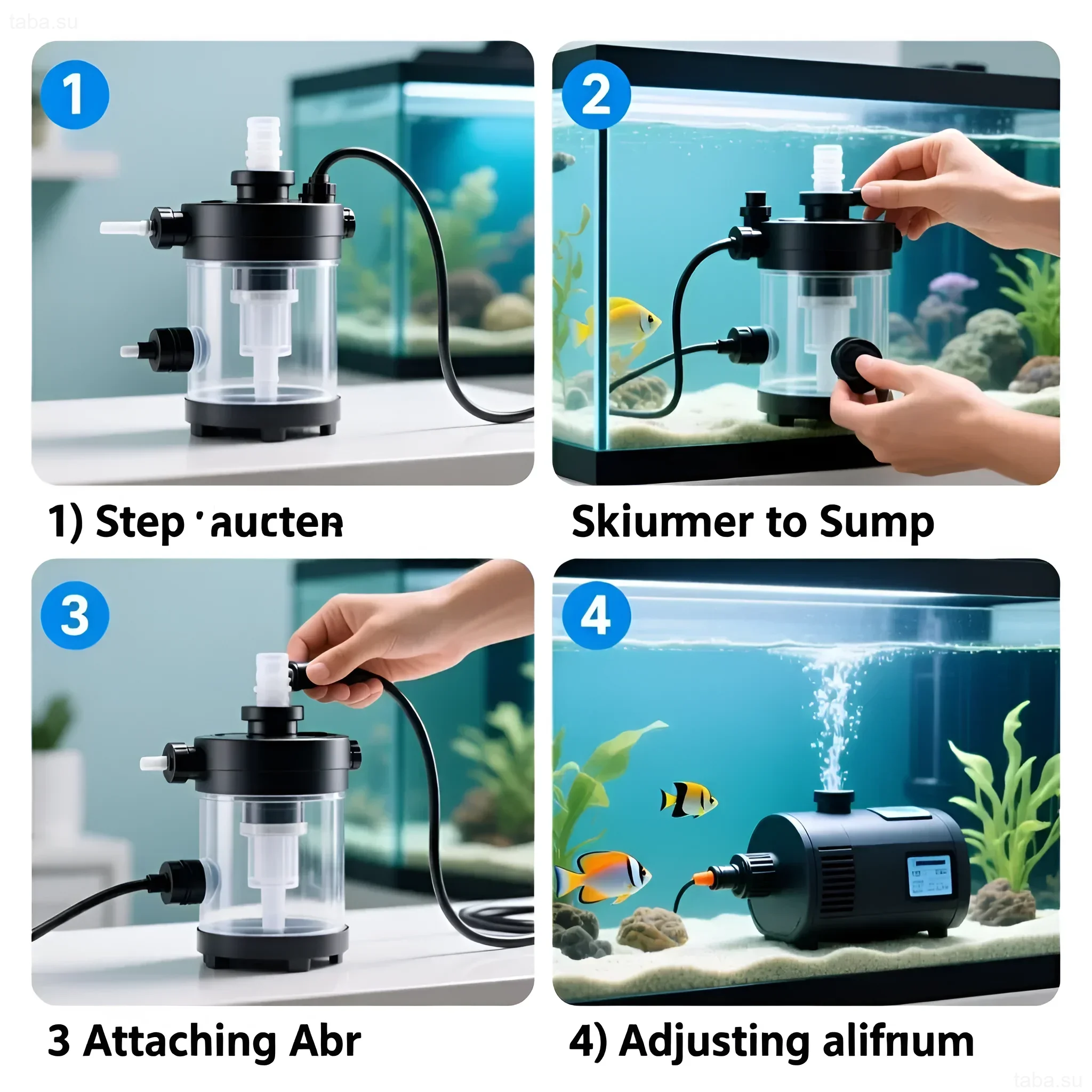

Step 1: Preparation for Installation

Ensure the skimmer fits the size of your sump. Most in-sump skimmers require a strictly defined water level in the sump compartment for correct operation.

Expert Tip: Always choose a skimmer rated for a water volume 1.5–2 times larger than your actual volume. For example, for a 300-liter aquarium, choose a model rated for 450–600 liters.

Step 2: Installation and Initial Startup

- Place the skimmer in the appropriate sump compartment.

- Connect the pump and start the device.

- Adjust the height of the neck or the water flow regulator so that the water level inside the reaction chamber is at the base of the neck, but not higher.

Step 3: Break-in Period

New skimmers, made of acrylic, are coated with a thin layer of manufacturing oils. These residues temporarily reduce water surface tension and interfere with stable foam formation.

Duration: 3 to 7 days.

During this period, the foam may be unstable, overflow, or be too watery. Do not try to adjust for perfect foam immediately. Let the device run until the acrylic is covered with a biofilm.

Step 4: Fine-Tuning

Tuning involves controlling the dryness (wetness) of the foam that enters the cup:

- Dry Skim: The water level in the chamber is low. The foam is thick and dark. It collects less volume, but the waste is highly concentrated. Ideal for stable, mature reefs.

- Wet Skim: The water level in the chamber is high. The foam is watery and light-colored, collected in large volumes. Used for rapid toxin removal, for example, after adding supplements or when starting a new system.

Protein Skimmer Maintenance: Cleaning, Part Replacement, and Troubleshooting

Regular maintenance is key to the skimmer’s maximum performance. A clogged pump or neck significantly reduces its efficiency.

Routine Cleaning

1. Collection Cup:

- Empty the cup 1–2 times a week (or more often if skimming wet).

- Rinse the cup under hot water to remove adhering organic deposits.

2. Neck:

- Organic deposits and “sludge” on the neck walls prevent foam from rising.

- Wipe the neck with a sponge or a special brush every 1–2 weeks. Many modern skimmers have automatic neck cleaning systems.

Deep Cleaning

Every 3–6 months, the pump and reaction chamber should be completely disassembled and cleaned.

- Disassemble the pump and remove the needle wheel (impeller).

- Soak all parts, including the chamber and impeller, in a solution of vinegar (1 part vinegar to 3 parts water) for several hours to remove calcium and organic deposits.

- Rinse all parts thoroughly with clean water before reassembly.

Troubleshooting

- Skimmer not producing foam: Check if the air intake is blocked. An oily film may have entered the aquarium (e.g., after using some medications or feeding).

- Constant overflow: The water level in the sump is too high or unstable. Check if a chemical contaminant that sharply reduces surface tension (e.g., soap or cleaning agents) has entered the water.

- Low foam level: The pump needs cleaning, or the needle wheel is damaged/clogged.

FAQ: Most Common Questions About Marine Aquarium Protein Skimmers

1. Can I turn off the skimmer at night?

Answer: Highly not recommended. The skimmer should run 24 hours a day, 7 days a week. It not only removes organic matter but also provides vital gas exchange. Turning off the skimmer can lead to a drop in oxygen and pH levels.

2. Is a skimmer needed in a nano-aquarium (up to 50 liters)?

Answer: Although nano-systems sometimes rely on frequent water changes and chemical media (e.g., granular iron oxide for phosphates), a skimmer will always be beneficial. For nano-aquariums, there are compact HOB models that significantly simplify maintaining stable water parameters.

3. Why does the foam smell so awful?

Answer: The smell is a sign that the skimmer is working effectively! You are removing concentrated, decomposing organic compounds (including hydrogen sulfide and other volatile substances) that would otherwise remain in the water. This confirms the necessity of regular waste removal.

4. How do I know if my skimmer is working at full capacity?

Answer: Effectiveness is determined by the volume and color of the collected waste. Ideal “dry” skim is a thick, dark brown, almost black liquid. If the foam is very light and watery, it may indicate that the water level in the chamber is too high or there is little organic matter in the system to remove (which can also be a good sign).

Interesting Facts About Protein Skimmers and Future Technology Prospects

Skimmer technology is constantly improving, making marine aquaristics more accessible and less labor-intensive.

- Historical Note: The first commercial skimmers appeared in the mid-20th century but were very bulky and used air stones. The widespread adoption of the needle wheel in the 1990s was a revolution in aquaristics.

- DC Pumps: The transition to direct current (DC) pumps has allowed aquarists to precisely control power and airflow, making foam adjustment incredibly accurate and energy-efficient.

- Automation: Modern flagship models can be equipped with built-in water level sensors that automatically shut off the skimmer in case of overflow. Automatic neck cleaning systems (using a mechanical scraper) are also actively developing to maintain constant efficiency.

Conclusion: A protein skimmer is not just an additional piece of equipment; it is a fundamental element of marine filtration. By understanding its principle of operation – the process of adsorbing hydrophobic molecules on the surface of microbubbles – an aquarist can effectively manage water quality and create a thriving reef ecosystem.